Description

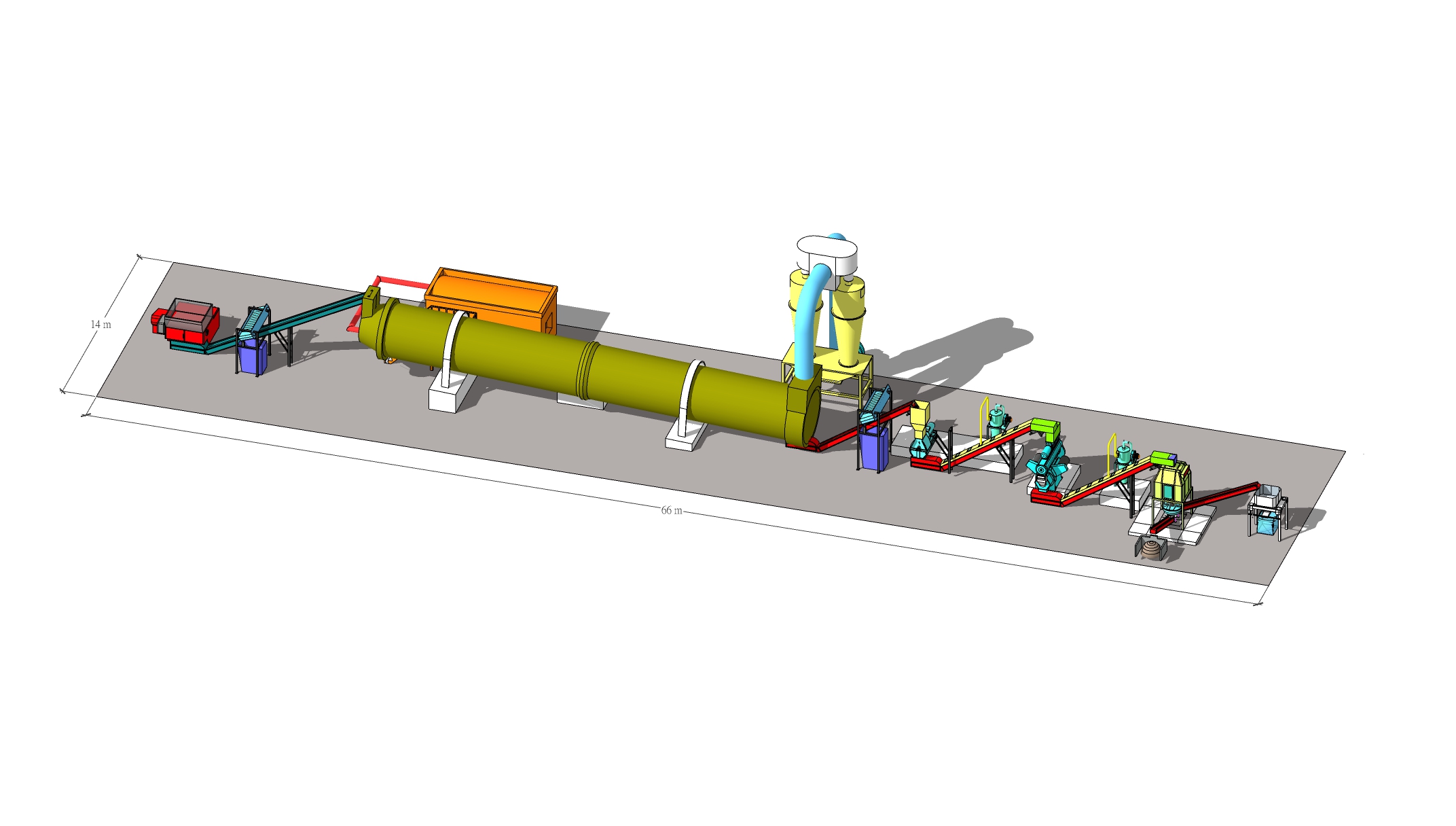

This production line effectively converts wood waste into biomass fuel, which not only saves storage space but it can aslo be an alternative fuel. To begin, a single-shaft shredder breaks down the wood waste into smaller pieces. The material is then dried by a machine to reduce its moisture content and improve its combustion efficiency. The grinder then pulverizes the material into the desired size for fuel production, and a bag filter removes any remaining dust to ensure a clean production line environment. The granulator compresses the pulverized material into wood pellets A cooling machine reduces the temperature of the pellets for safety, and a screening machine filters the pellets to ensure they meet the desired size. Finally, the pellets are then packaged at the packaging station so that they can be easily transported and stored.