Description

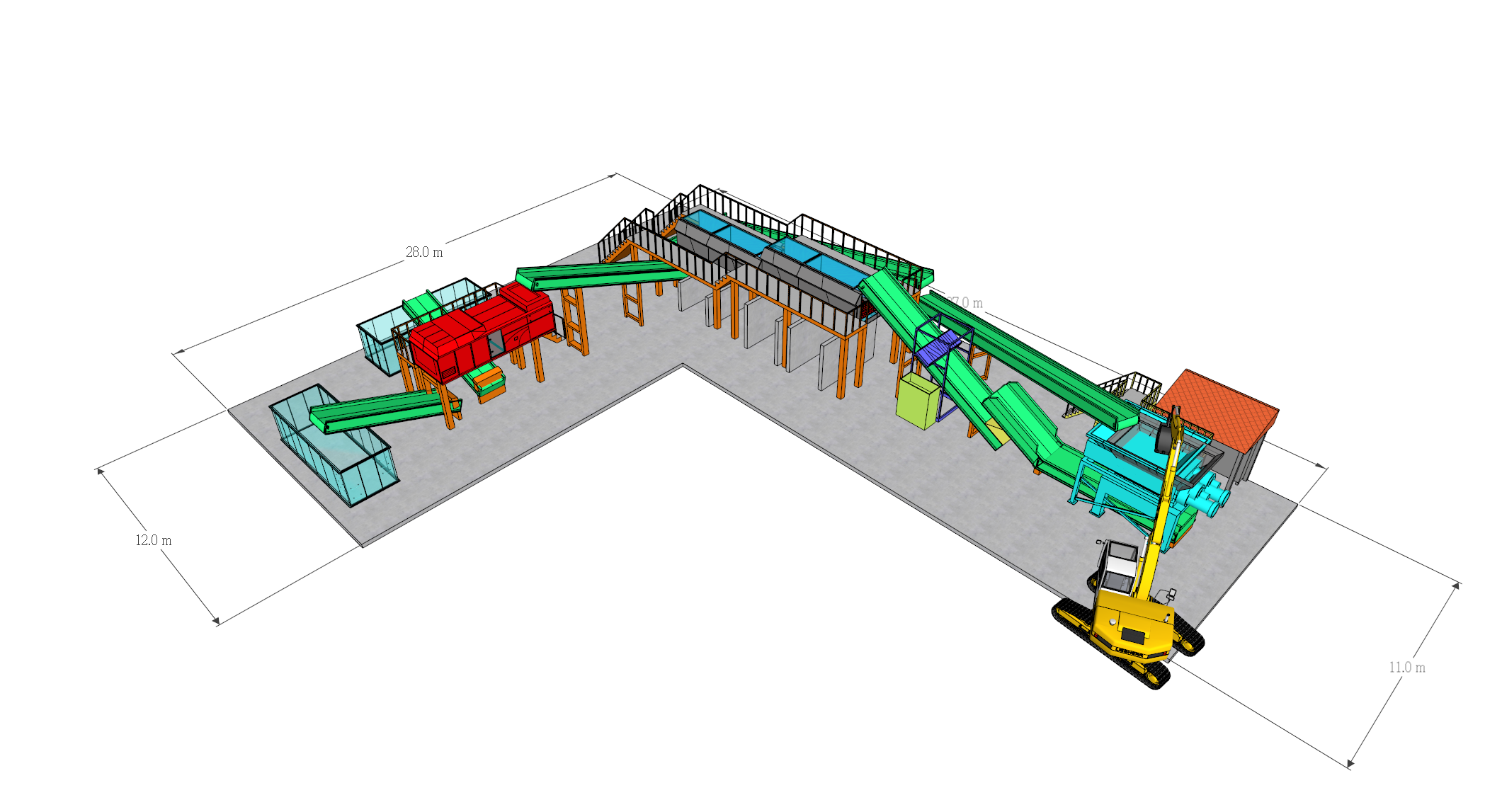

This production line is designed specifically for the production of RDF-2 fuel and, through innovative production line design, waste can be transformed intovaluable raw materials. First, waste is fed into a primary crusher to be crushed into smaller materials. Then, the magnetic separator filters out materials containing iron, before passing through a screening machine to remove small stones and glass. In this process, materials with a size > 100mm will be sent back to the primary crusher, while materials with a size ≤100mm will be sent to the windsifter to remove heavier materials and retain lighter combustible materials. The final RDF-2 fuel has a calorific value ranging from 2800 to 3000 and is suitable for current incinerators. It will help to decrease the incinerator’s slag ratio and increase the efficiency of the incinerator