Description

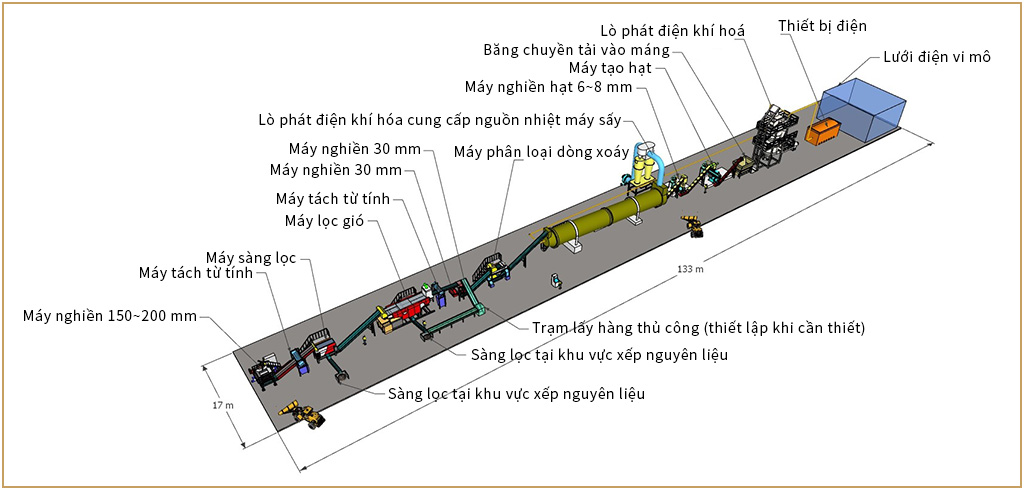

The special feature of this production line is its ability to transform waste into RDF-5 fuel. Firstly, the dual-shaft shredder is used to shred the waste, followed by the magnetic separator to filter out materials containing iron. Next, the star disk sieve filters out particles in the material, while the windsifter is responsible for sieving out heavy, non-combustible materials such as glass and stones during the filtering process. The material is then further shredded by a secon-stage shredder. The eddy current separator then filters out non-ferrous metals, and the dryer dries the material to reduce its moisture content and increase combustion efficiency. After the material is ground to the desired size by the grinder, the granulator compresses and shapes the material into RDF-5 fuel. RDF-5 fuel has a high calorific value and can be used in gasification power generators to provide power for the production line, as well as provide a sustainable solution for waste management and energy production.