Description

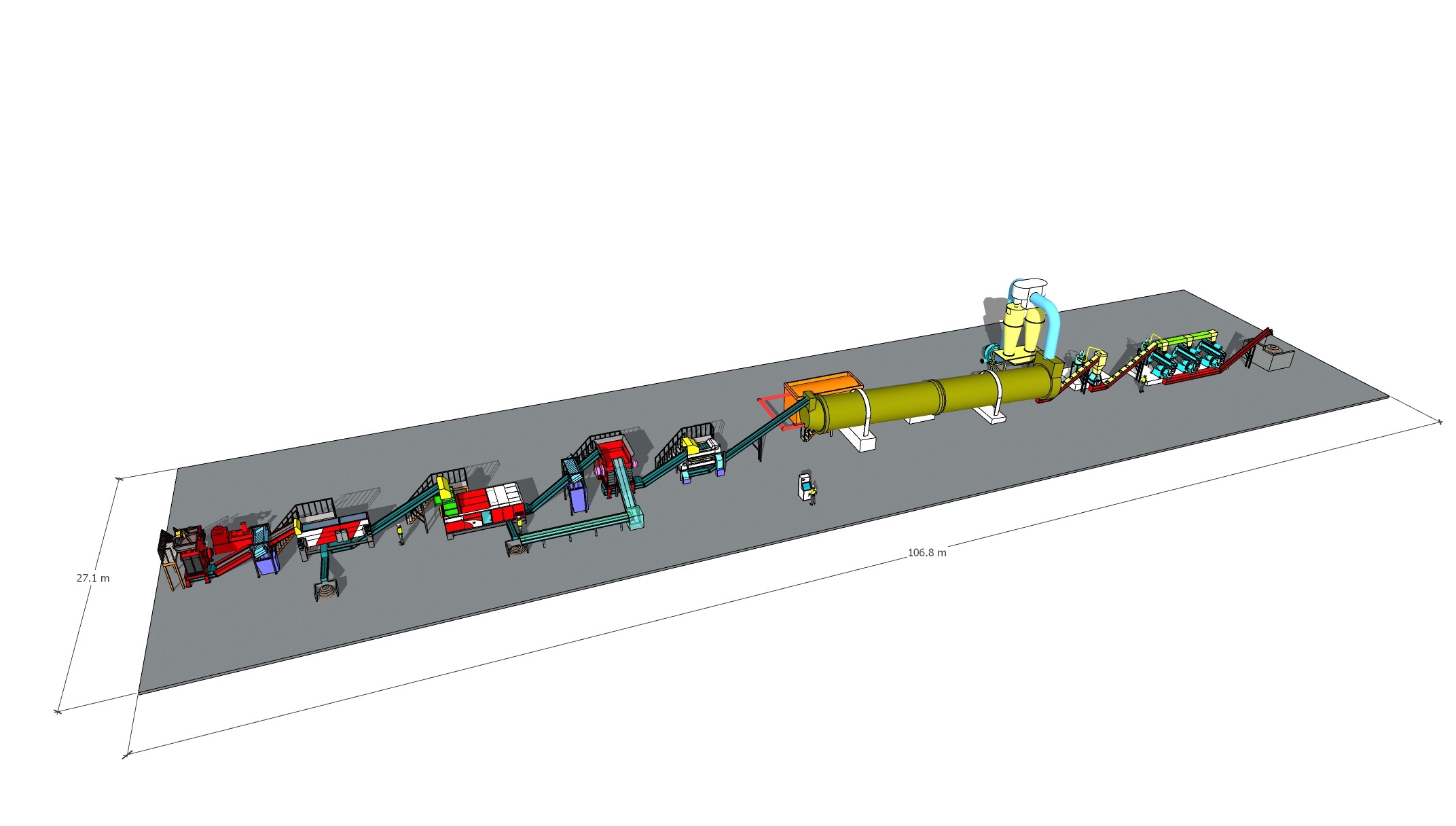

RDF-5 fuel is an important material for environmental sustainability, and this production line is designed to transform waste into RDF-5 fuel. First, the waste is sent to the primary shredder for crushing into smaller pieces. Then, the magnetic separator is responsible for filtering out iron-containing substances, and the star disk screen is used to filter out particles. The windsifter is responsible for removing non-combustible heavy objects, such as glass and stones, to improve resource recovery efficiency. After the initial filtering, the material is going through the magnetic separator again and then further crushed into smaller sizes by the second-stage shredder. Afterwards, the eddy current separator filters out non-ferrous metals, and the drying machine dries the material to reduce moisture and improve combustion efficiency. The granulator then compresses and shapes the particles into RDF-5 fuel. RDF-5 fuel has a high calorific value and can be used as an alternative fuel, reducing the use of natural fuels.